Received my copy on Ebbro MP4/30 kit and could not resist starting it. Kit is very basic and simple. I anticipate no issues with kit and hopefully can get it done relatively fast. Only 2 concerns to address. First is missing brake detail - no rotors, no calipers and no covers. I'll have to scratch build covers and use resin copies of rotors and calipers from another kit. Second is the choice of proper colour. Neither TS40 or TS14 seems to be correct. If I cannot find better match in my own stock, I will probably go with recommended TS40.

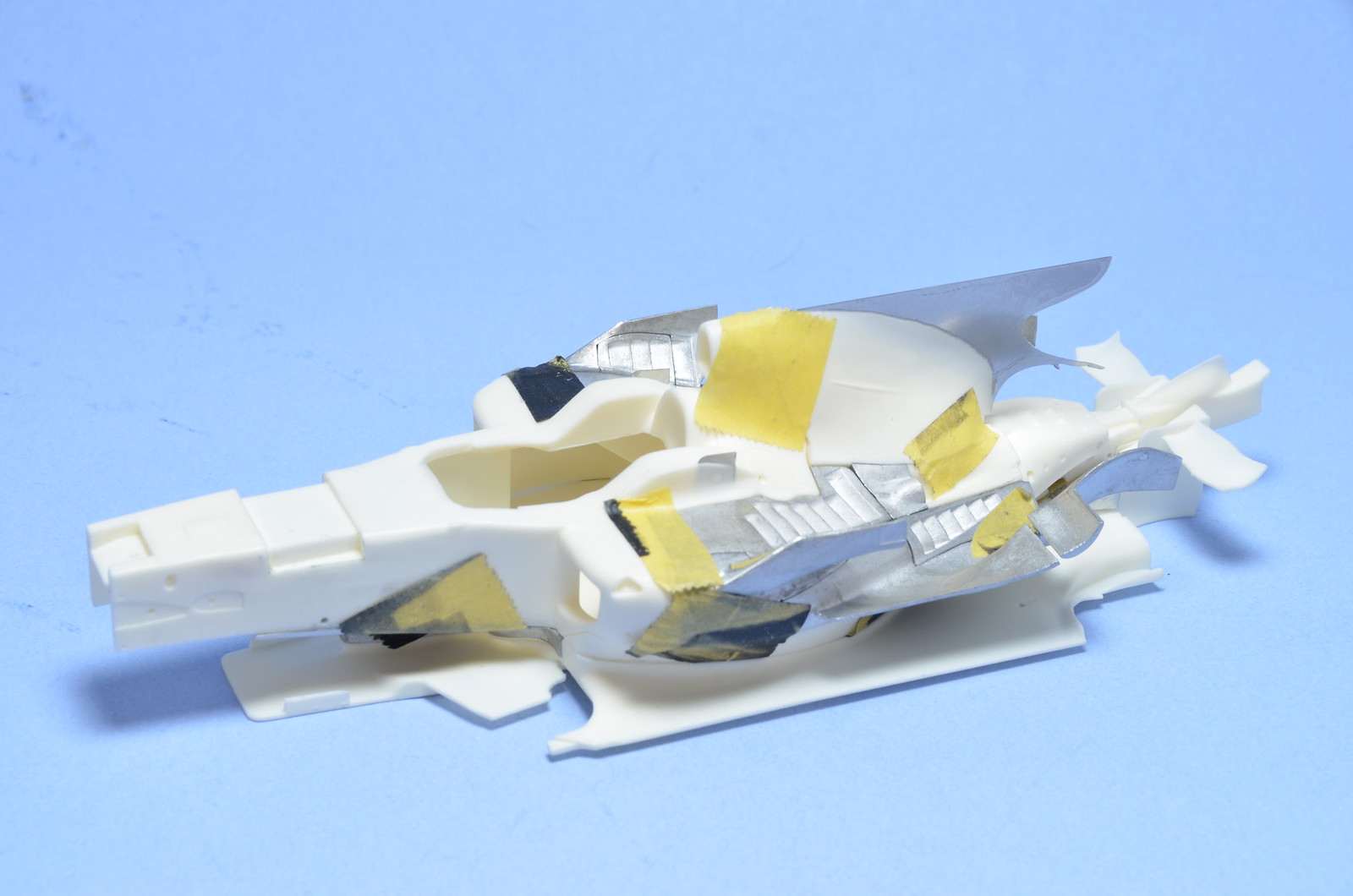

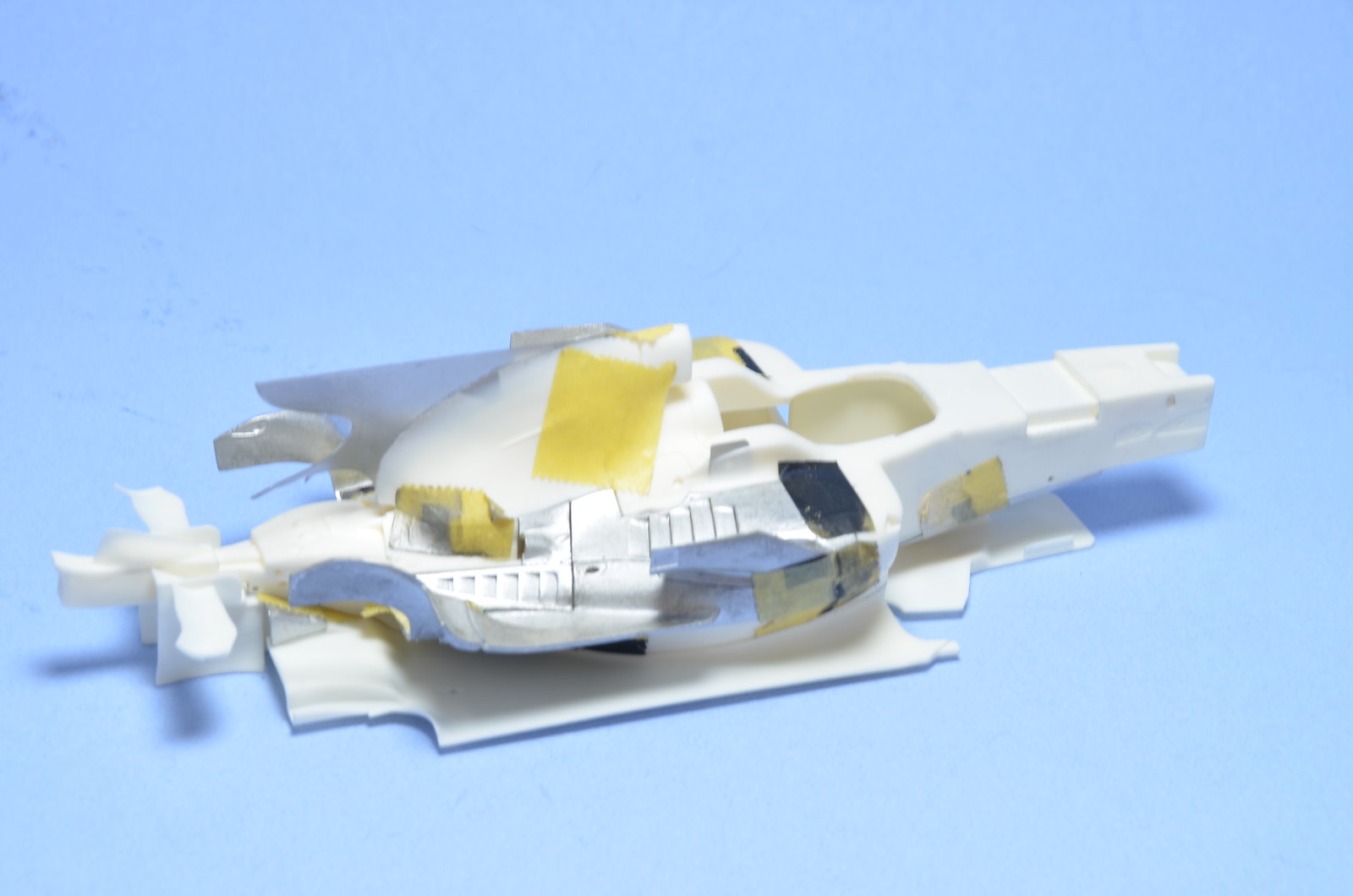

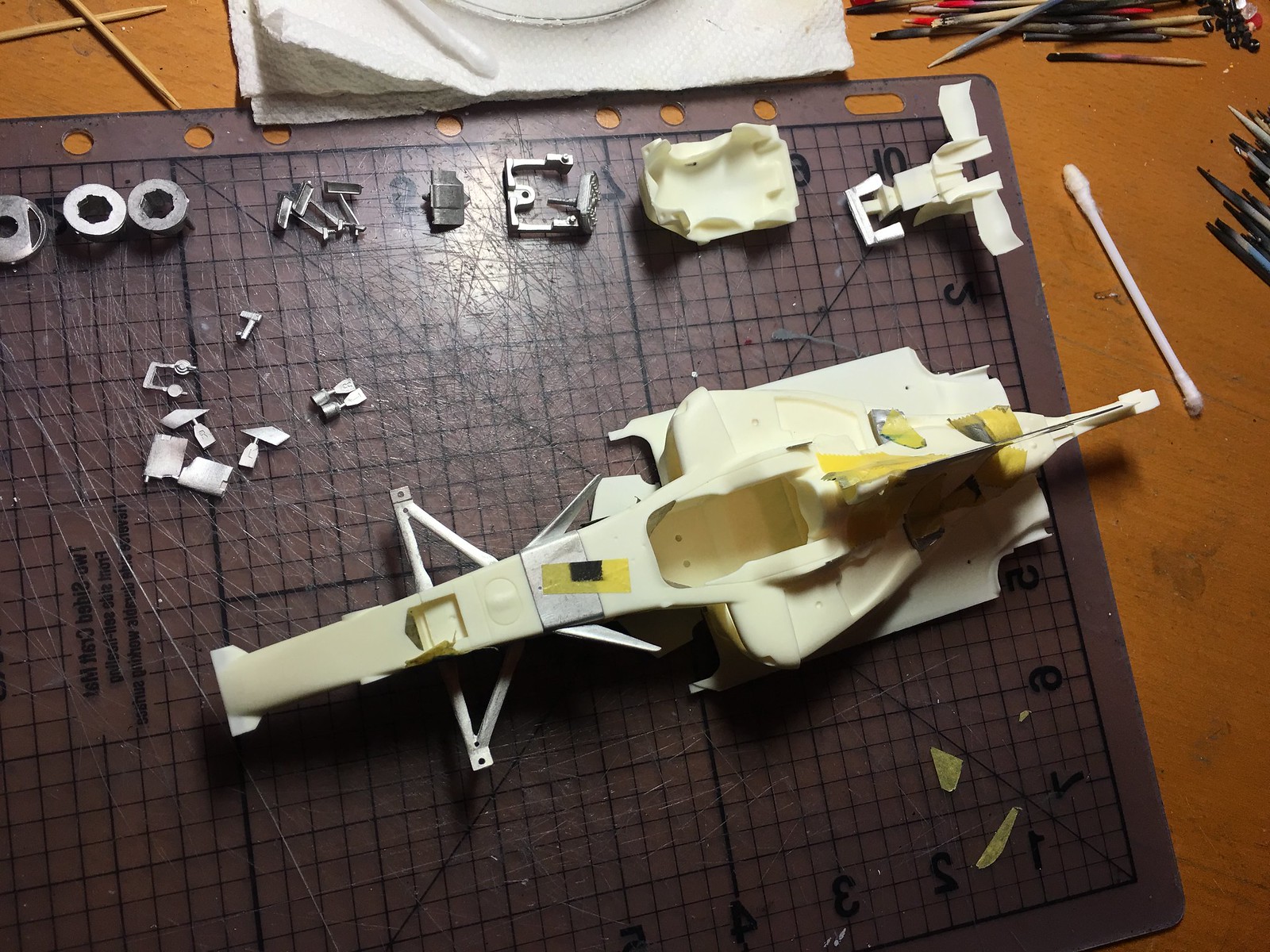

First step is traditional test fit assembly. Fit is very good on this kit.

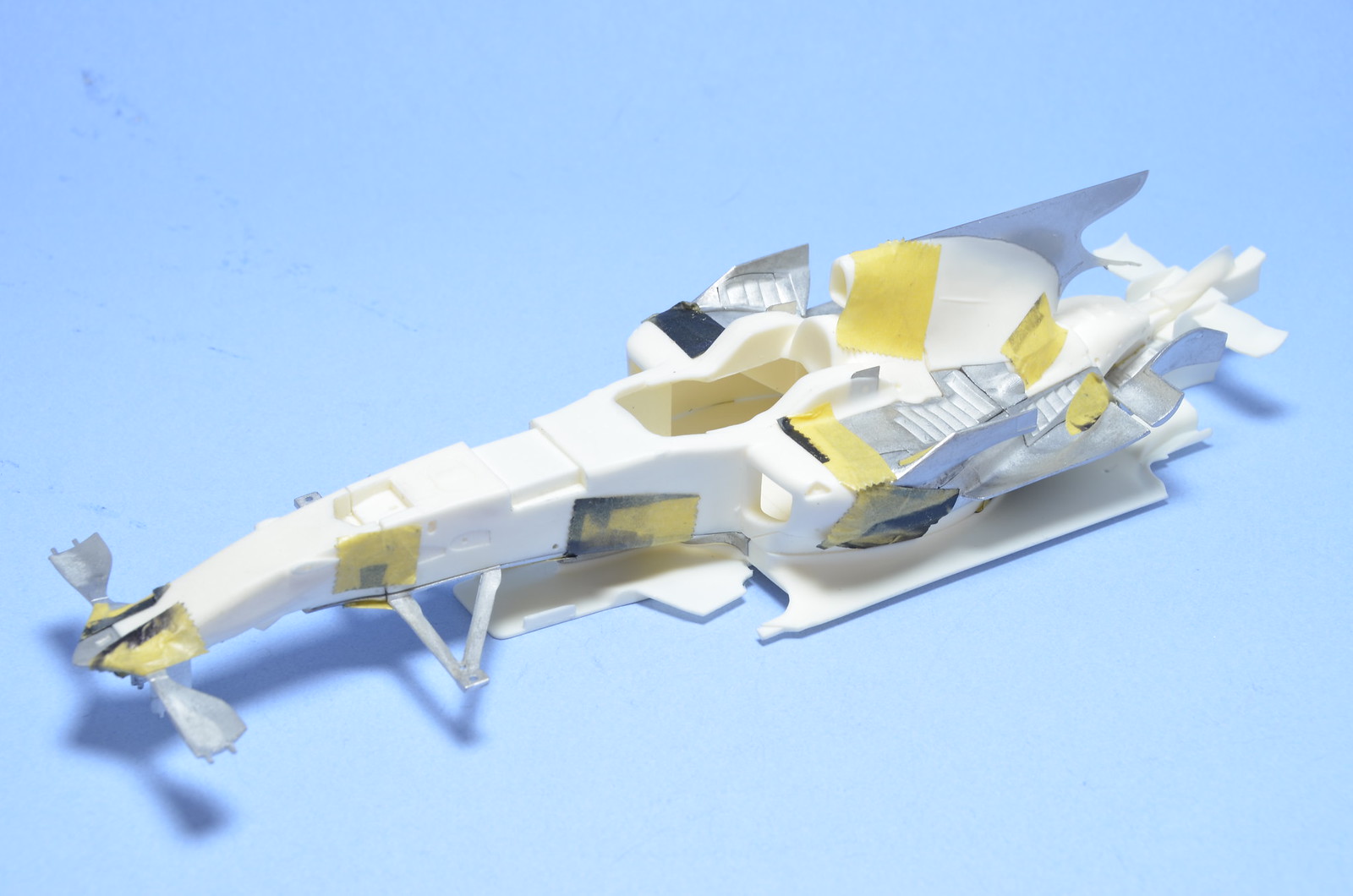

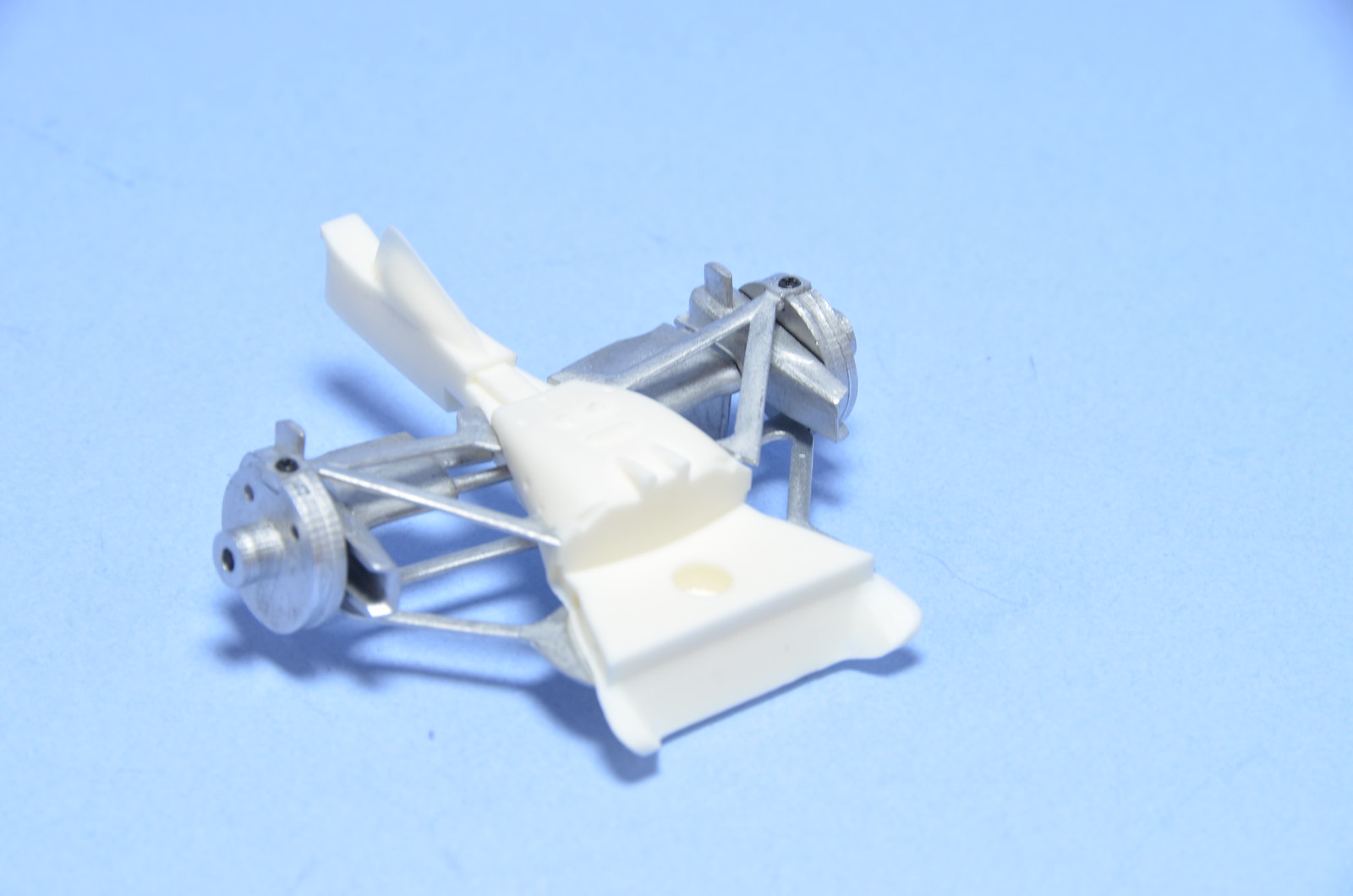

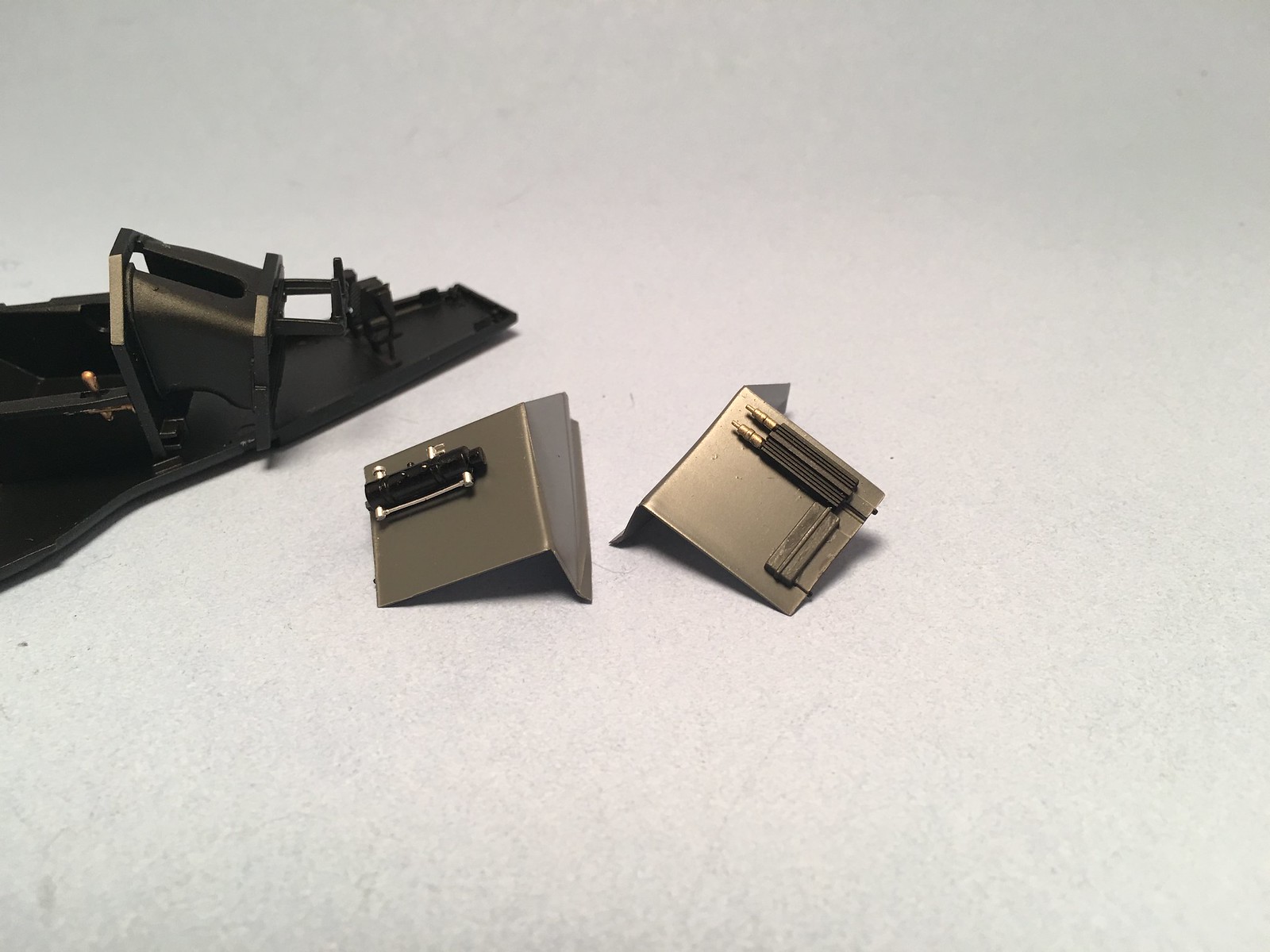

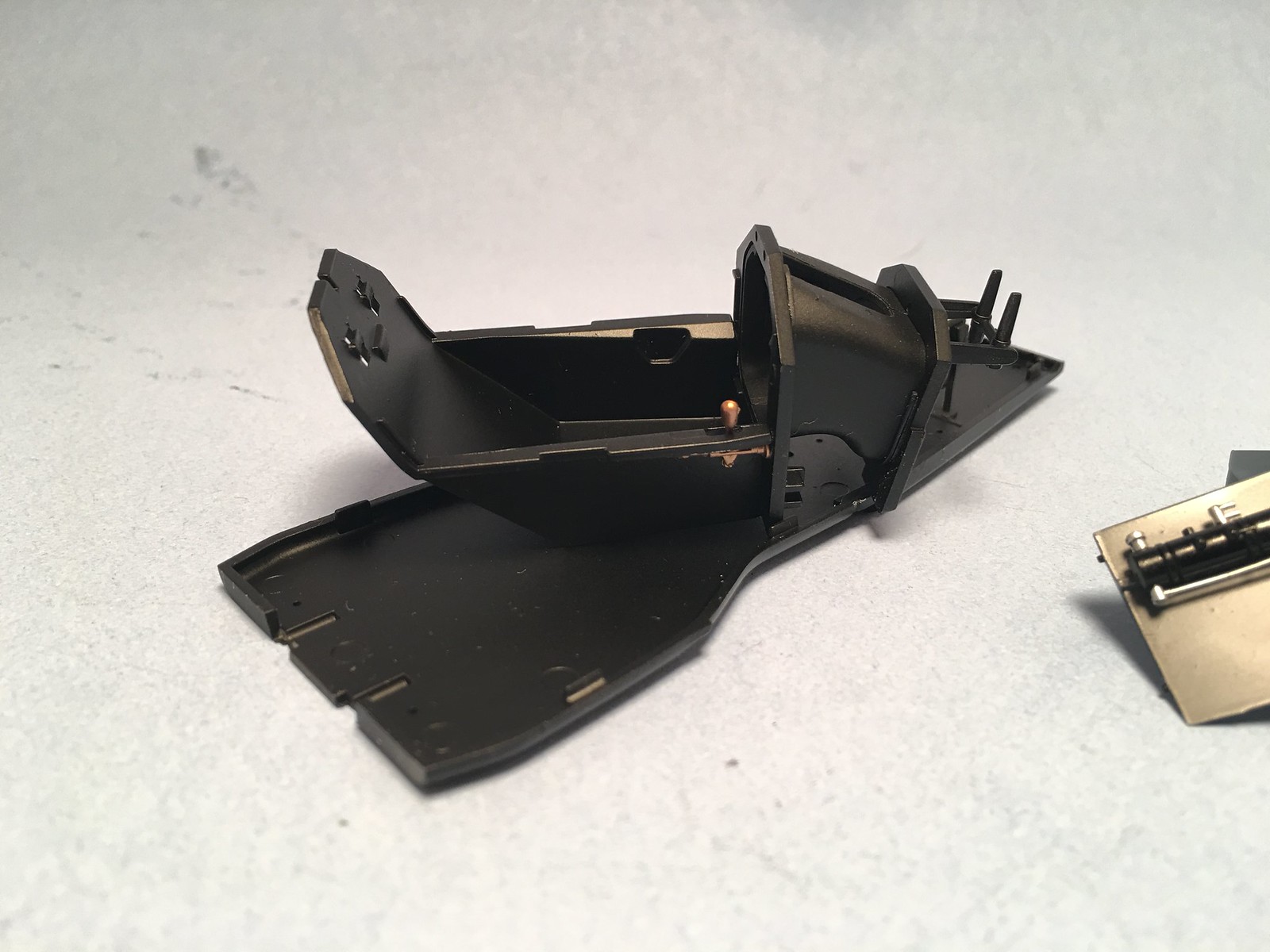

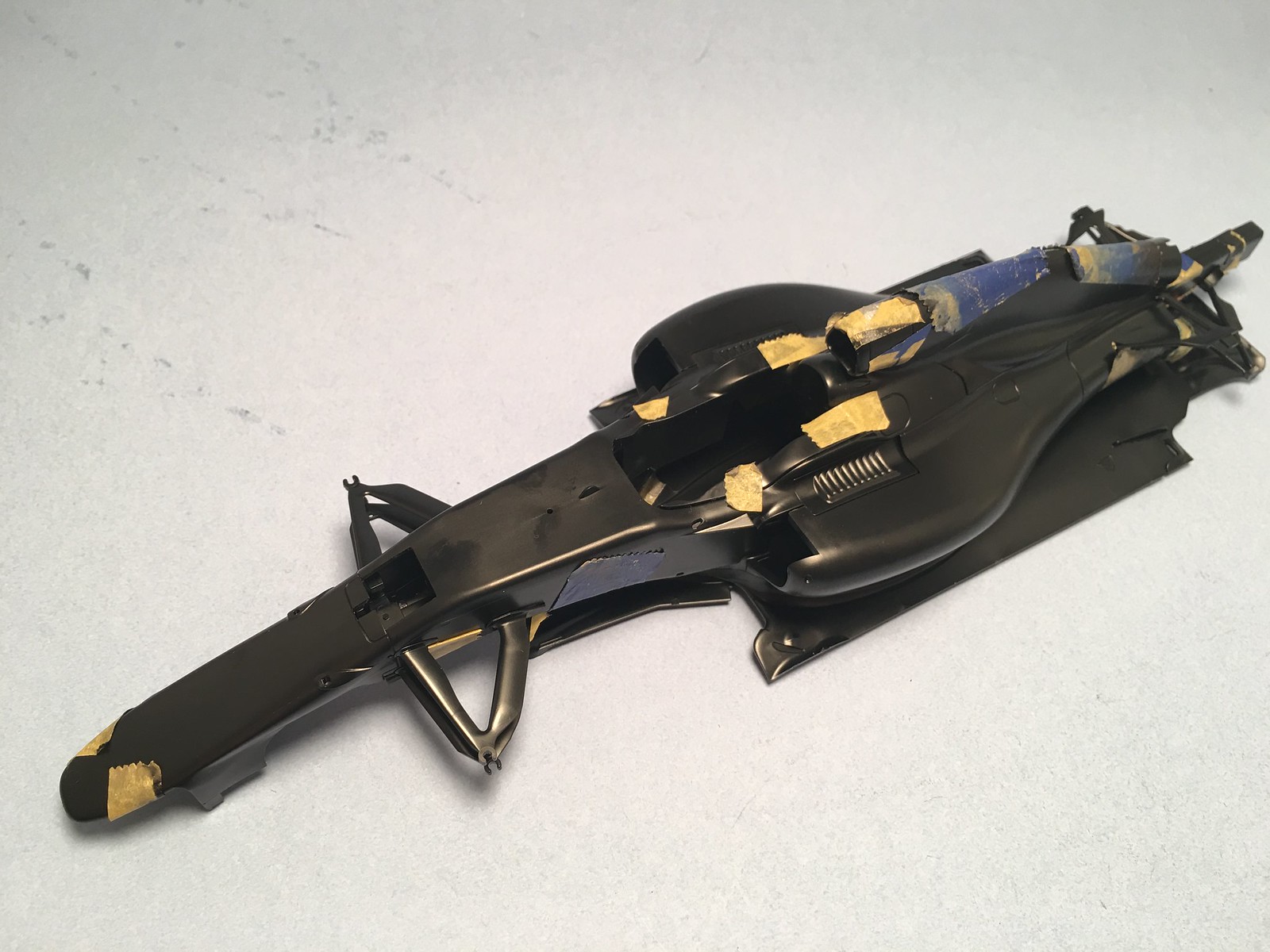

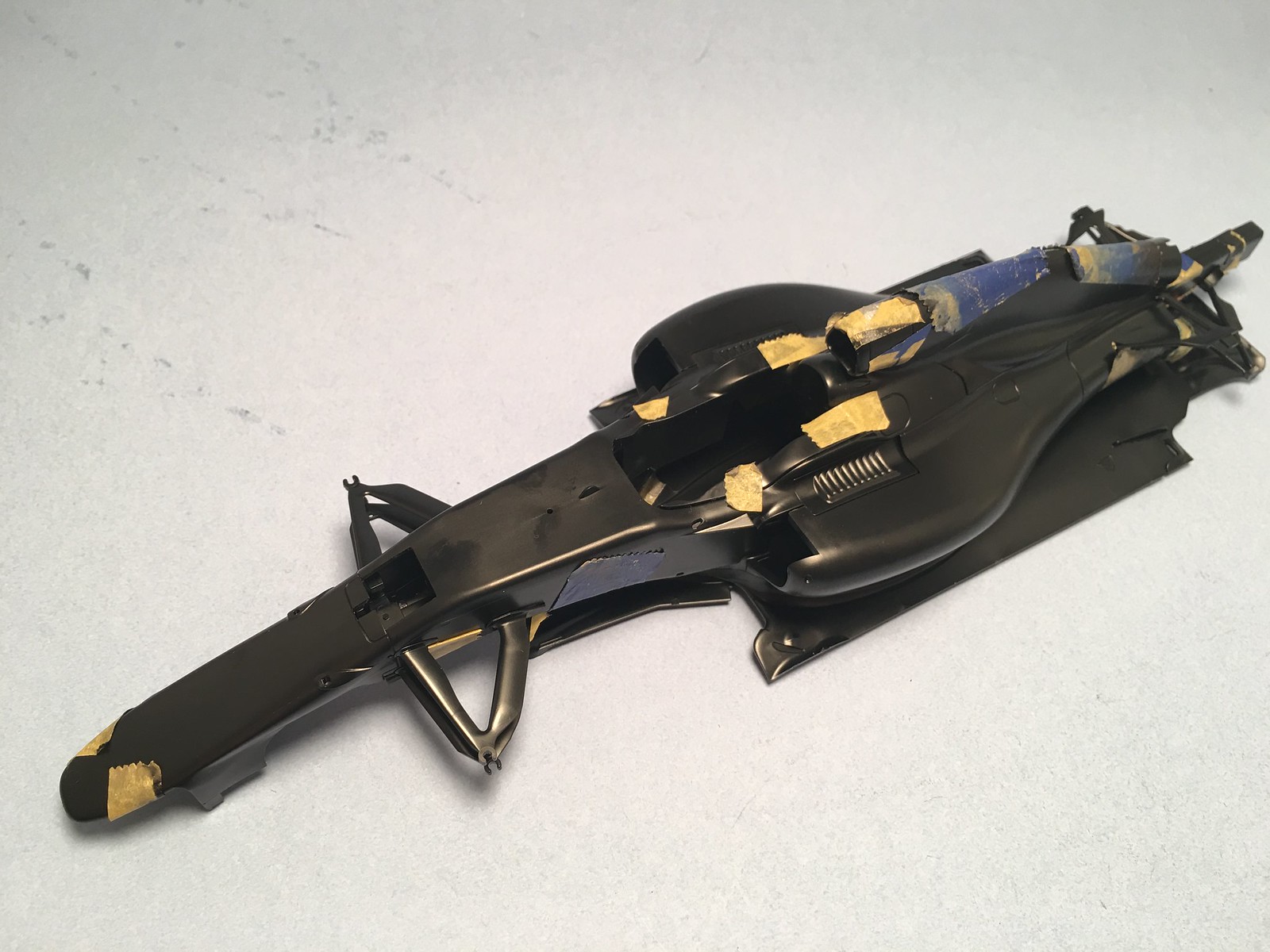

Next step was to glue together as much parts as possible before paint. Assembled floor parts, upright details, gearbox and exhaust pipe. Then assembled all body parts into curbside shell. Kit does not have any engine at all. Next step will be putting seams and injection marks and preparing surfaces for primer.

First step is traditional test fit assembly. Fit is very good on this kit.

Next step was to glue together as much parts as possible before paint. Assembled floor parts, upright details, gearbox and exhaust pipe. Then assembled all body parts into curbside shell. Kit does not have any engine at all. Next step will be putting seams and injection marks and preparing surfaces for primer.