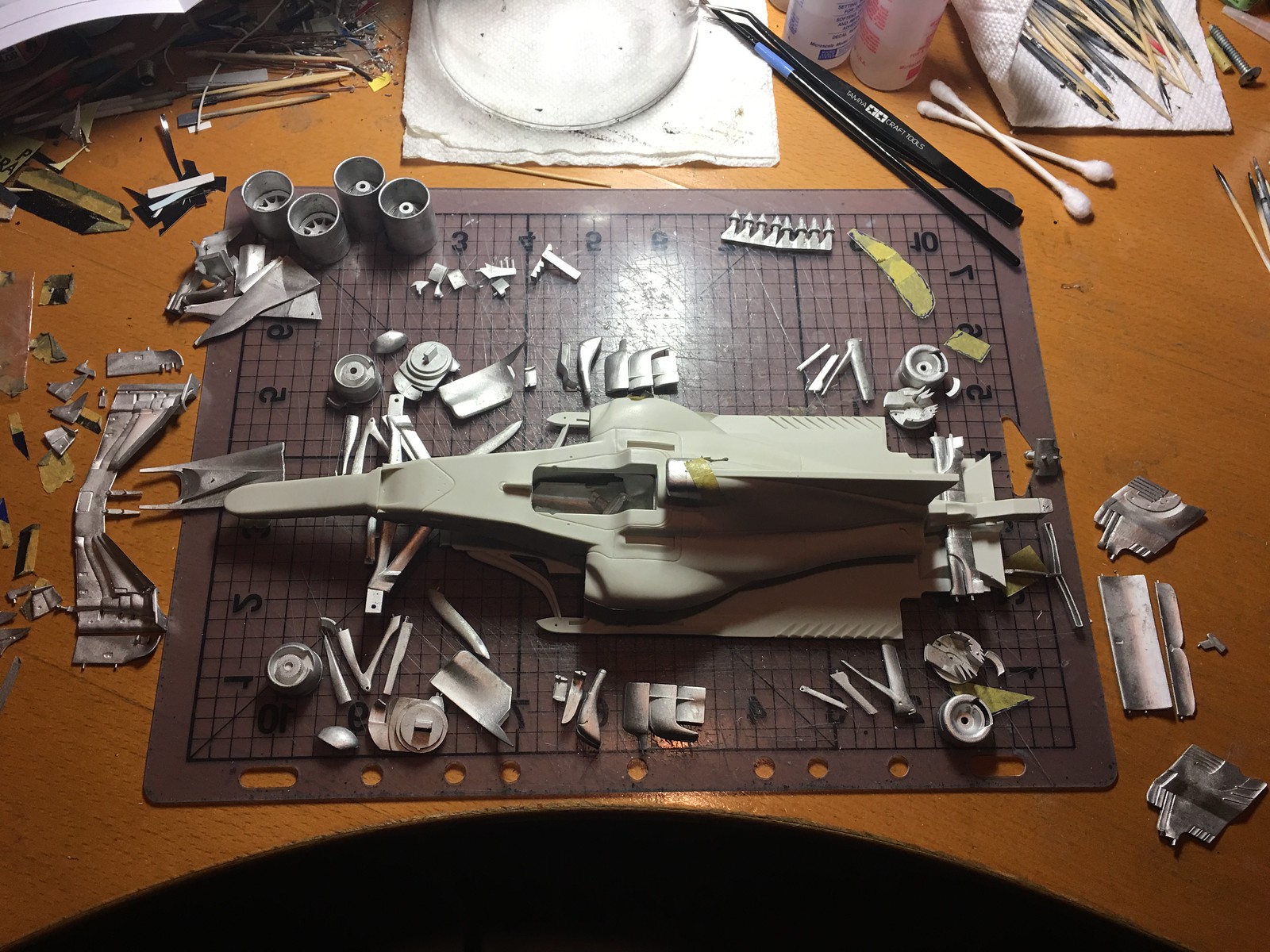

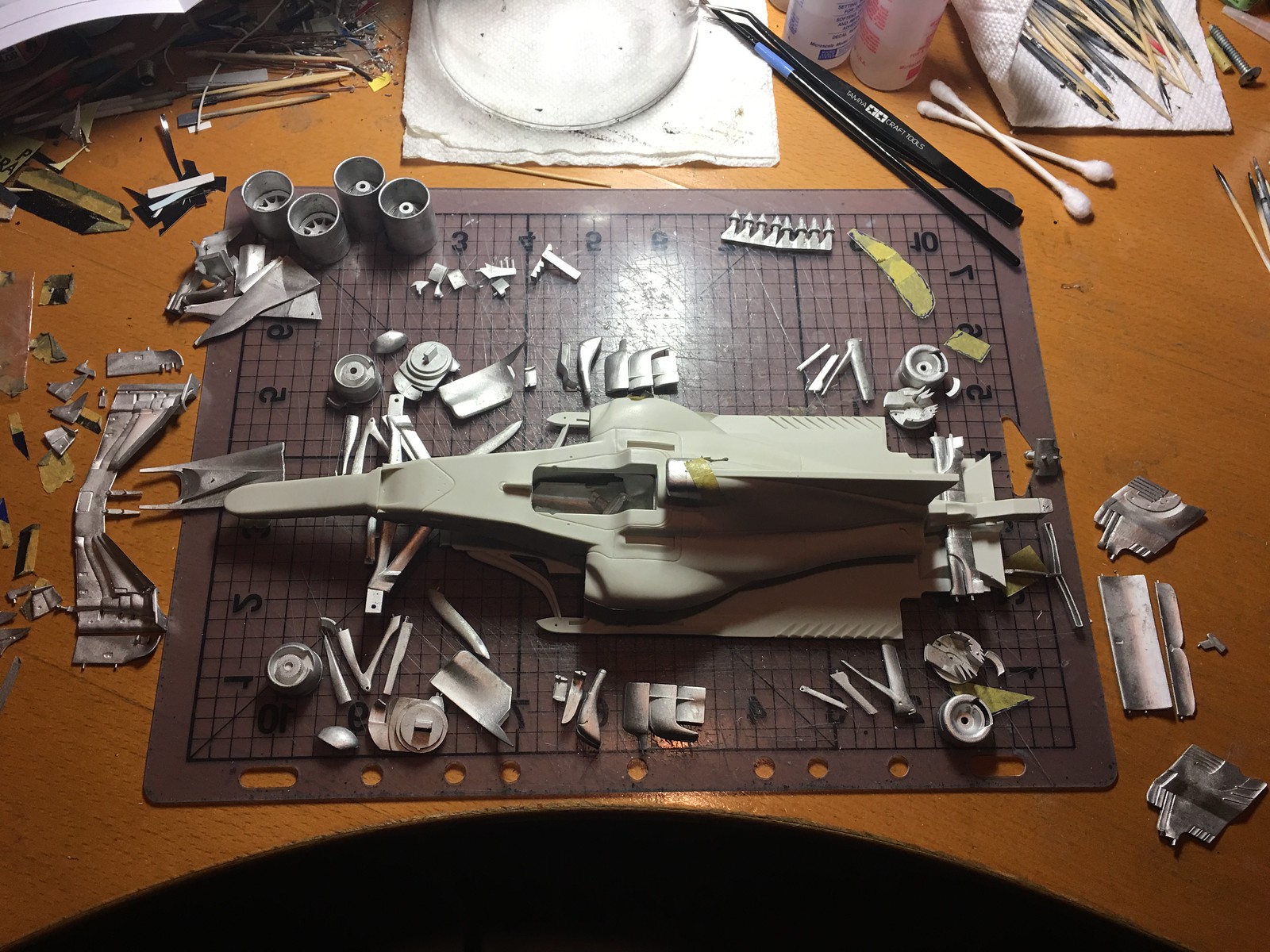

Received my kit little over 2 weeks ago. Since then was itching to start it. Have been collecting reference photos and thinking about what to do with thick fin. Last night made a little start. Usual clean up of parts and test assembly steps started.

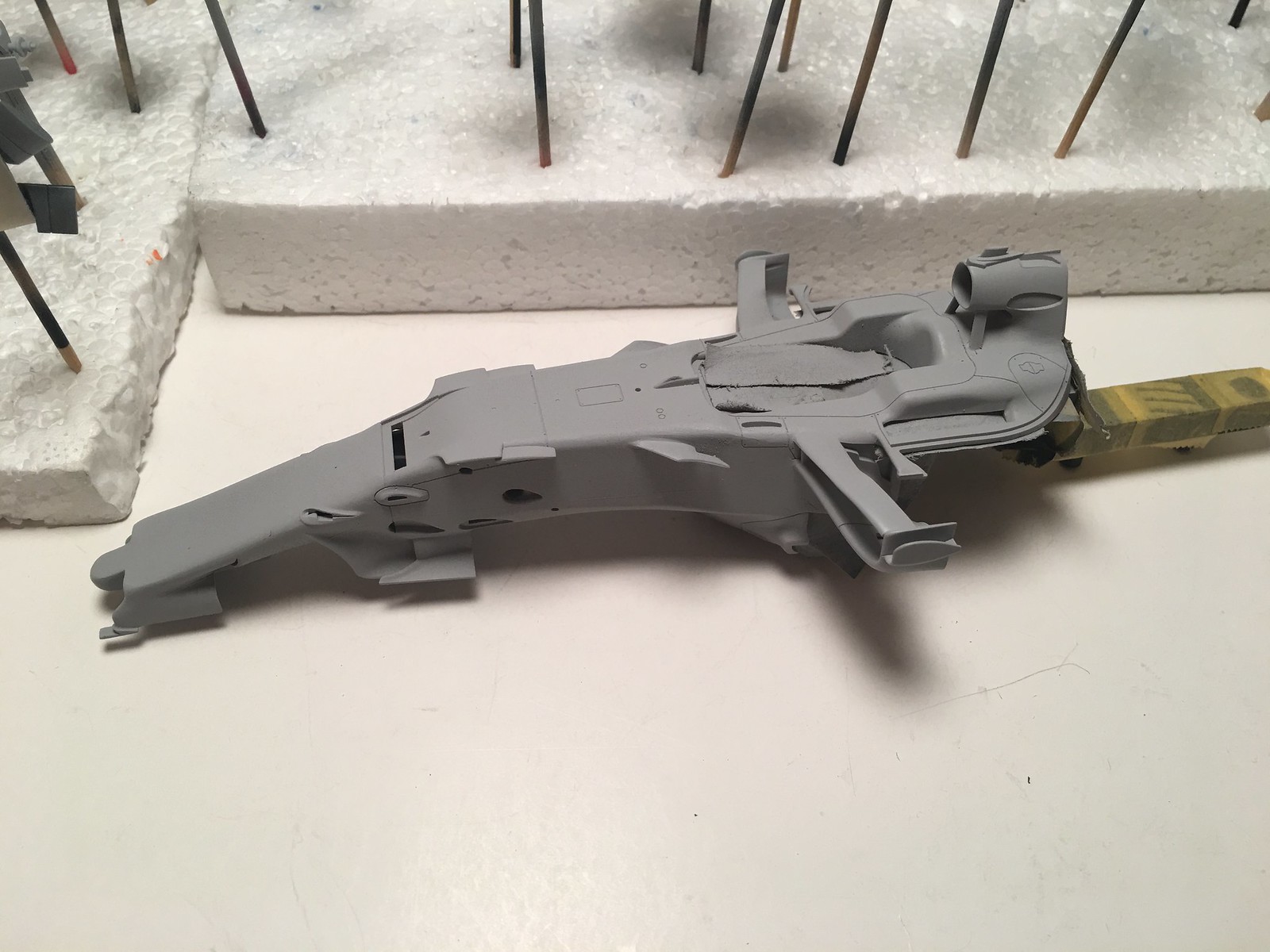

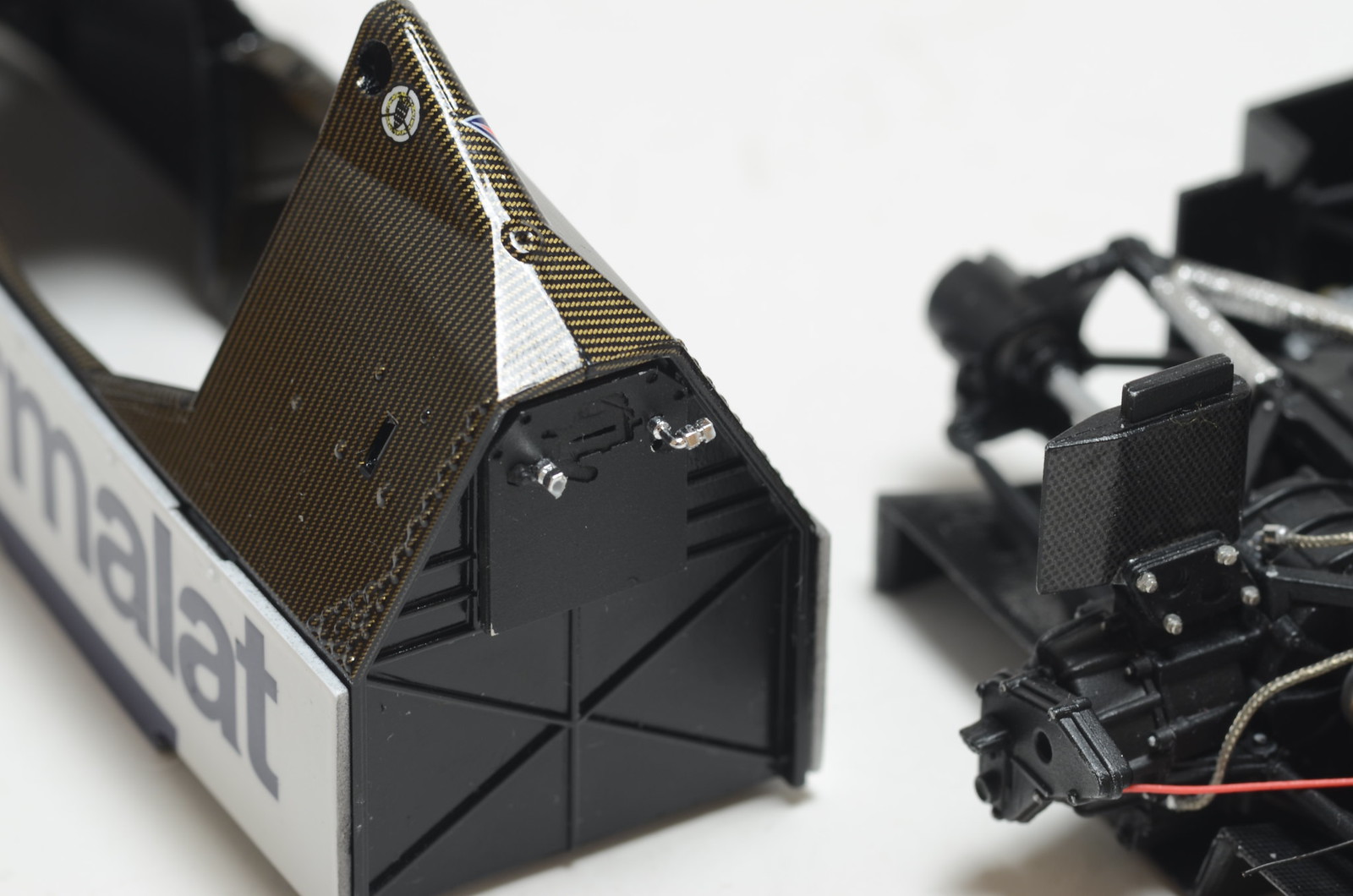

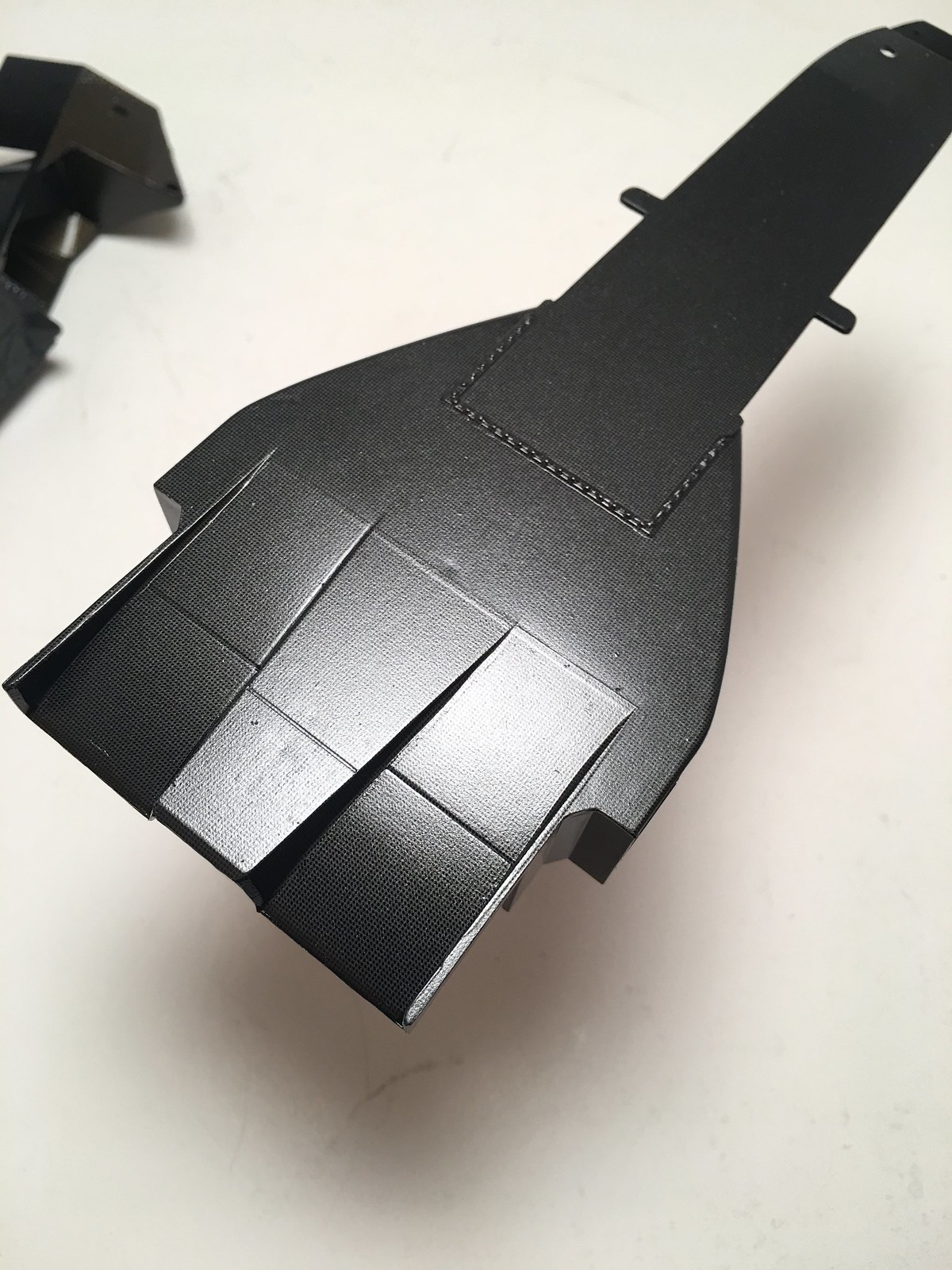

Cannot understand why, by S27 made fin very thick. To be in scale it should have been paper thin. Instead it is about a millimeter thick, this in scale would work out to 20mm in rear size car. On all the ref photos it looks much thinner on real car. In case or US GP matter is complicated by air vent, which was integrated into fin. S27 provides metal parts to replicate that vent. However parts, when assembled, add to same millimeter of thickness. My earlier idea was to remove resin fin completely and replace it with thin copy made out of brass sheet. After examining parts, I don't think any more that's possible. Still looking for solution. If any one has ideas, pleace chime in.

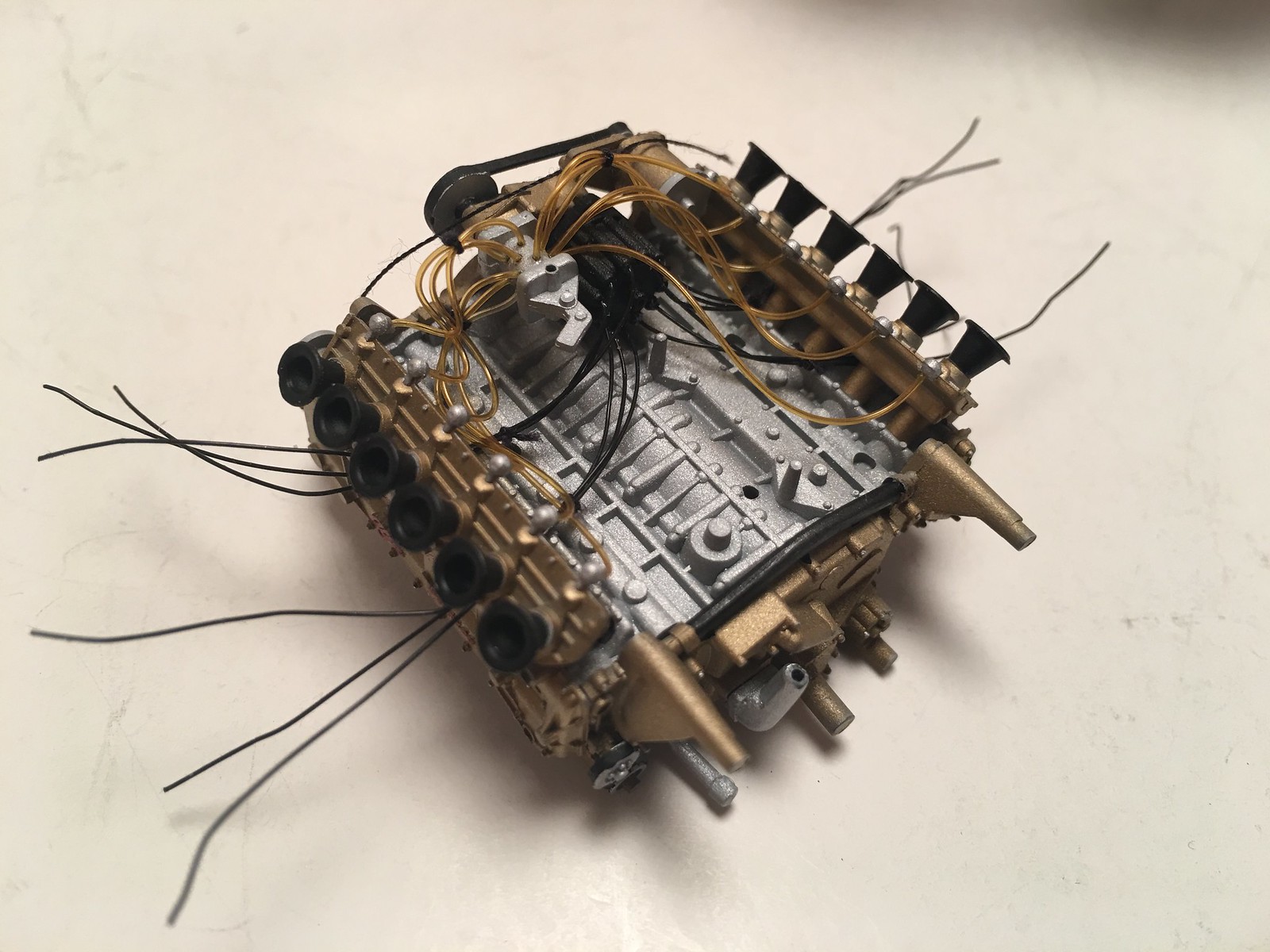

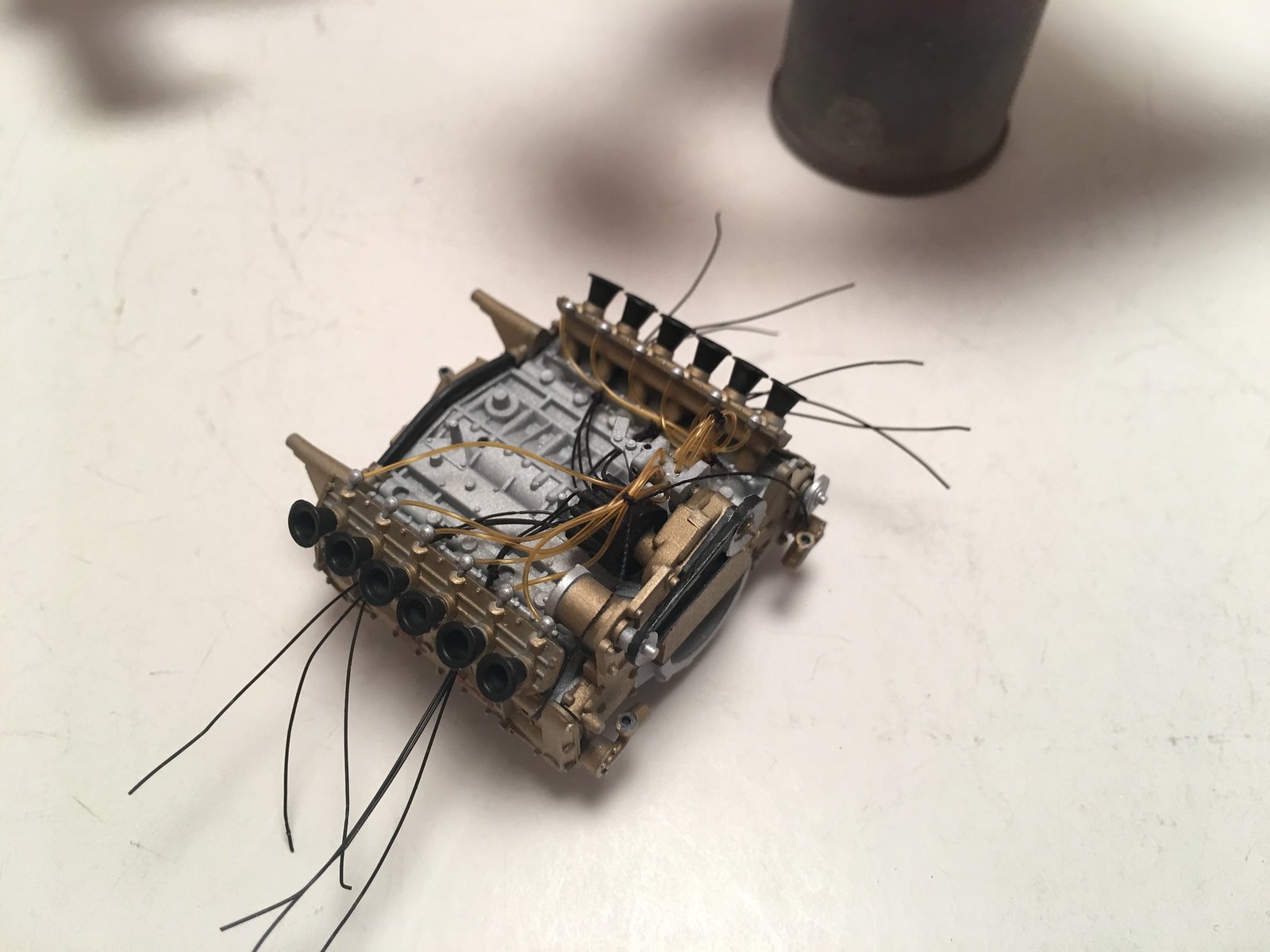

Over quality of the kit seems better then many previous offerings from S27. I am pleased with many relatively faithfully representled aero bits and details. Some compromises are strange, but I think kit presents a decent base to build good model. Just need to work out what to do with that awful thick fin.

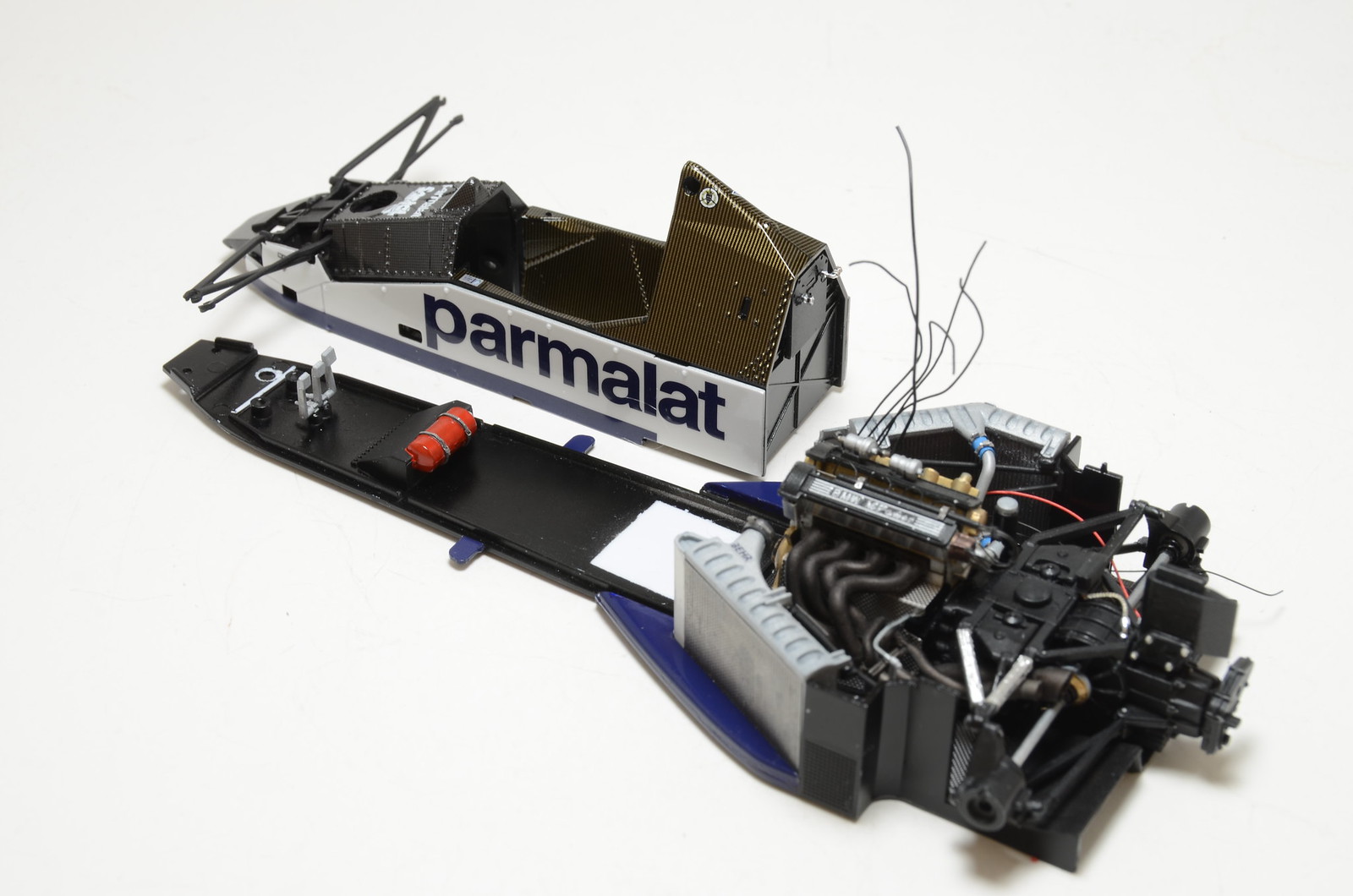

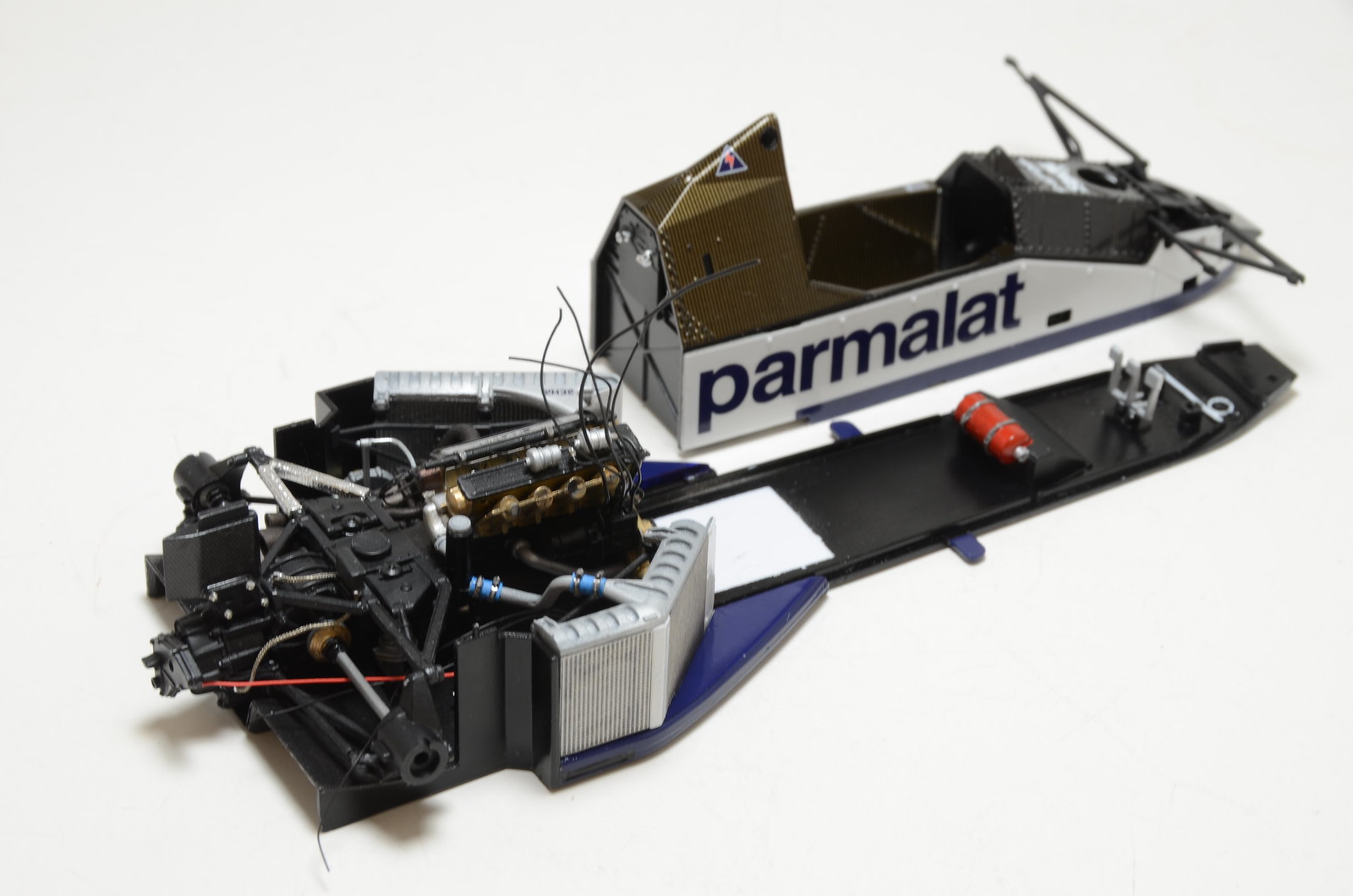

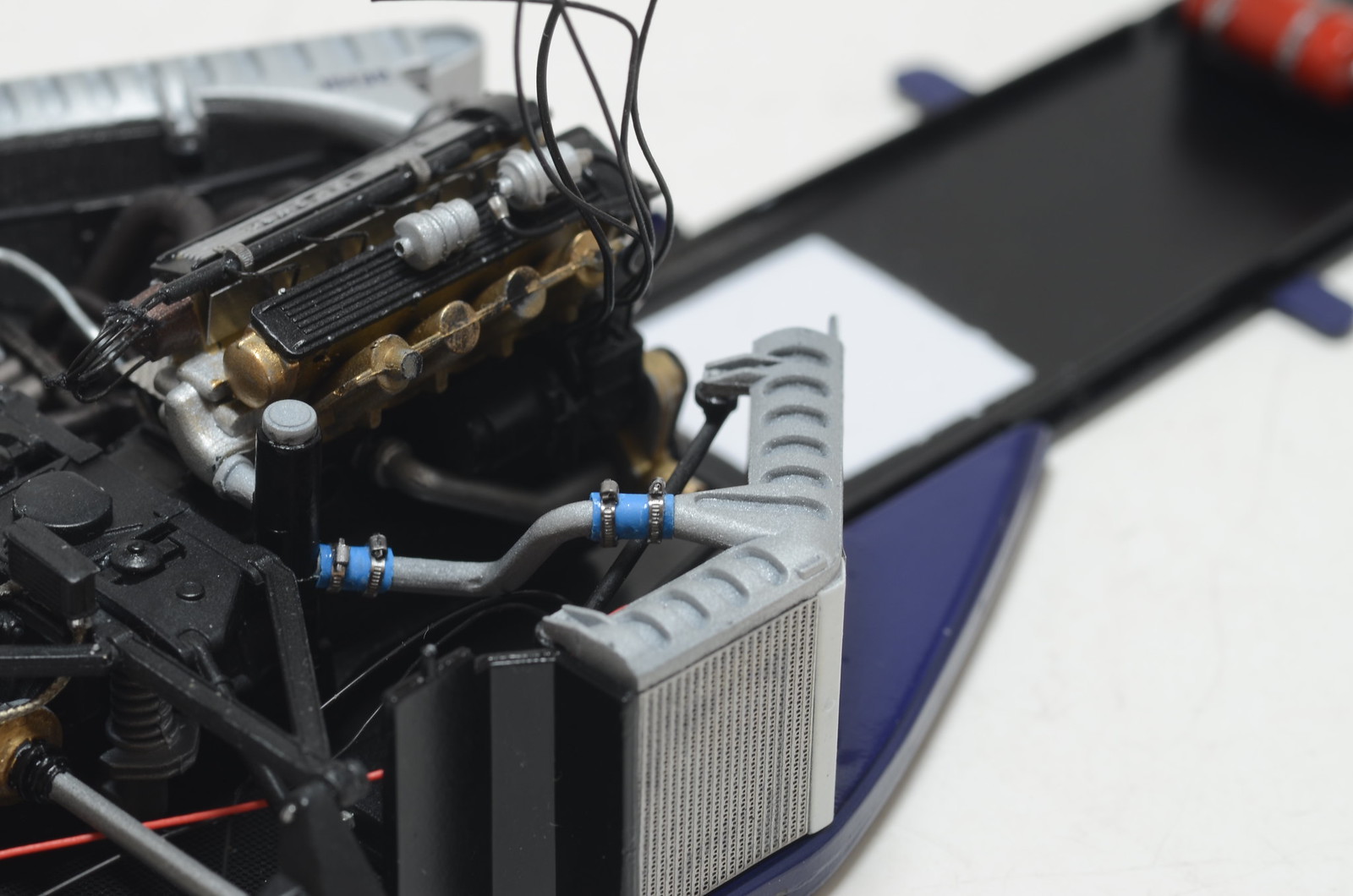

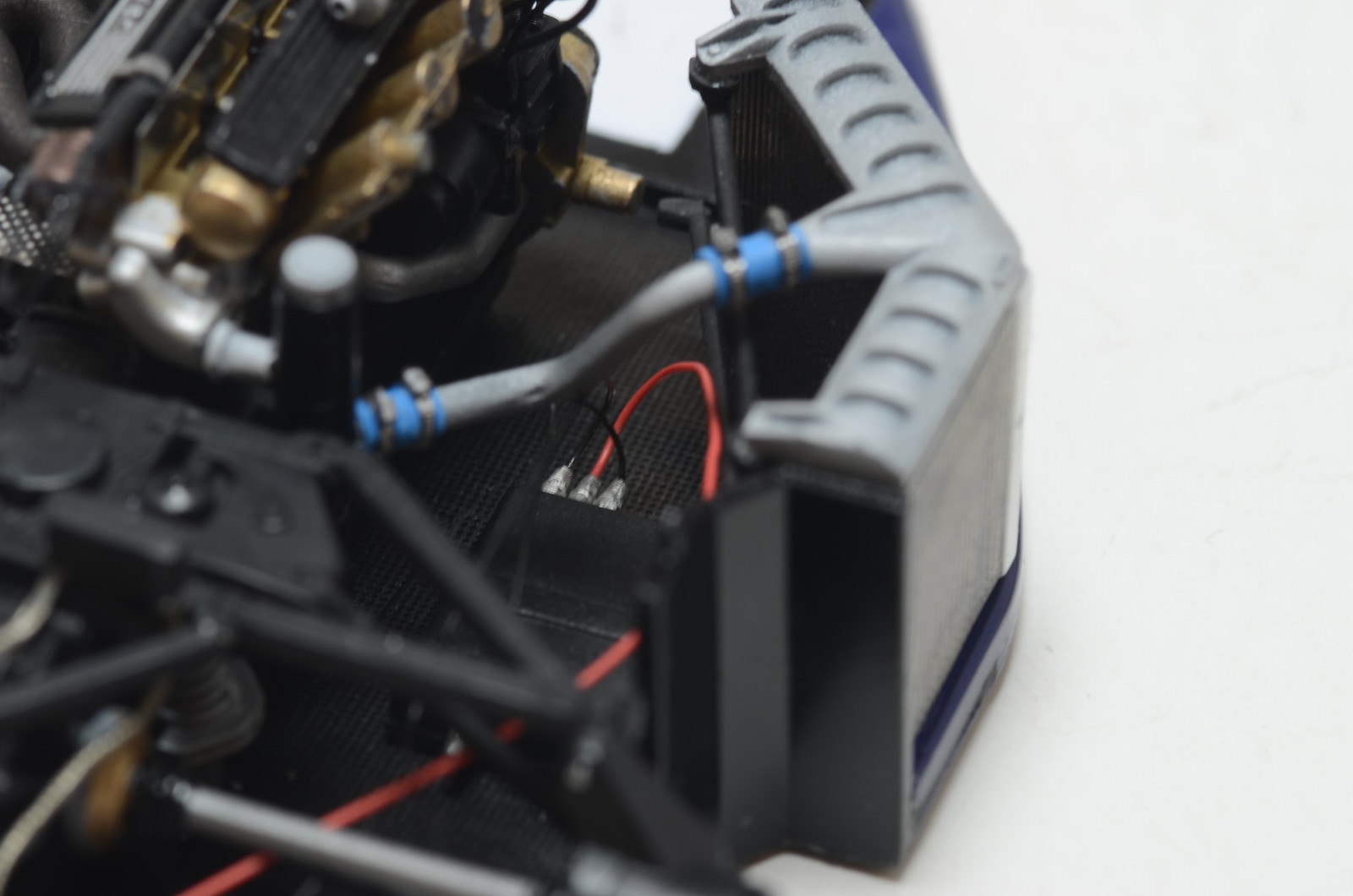

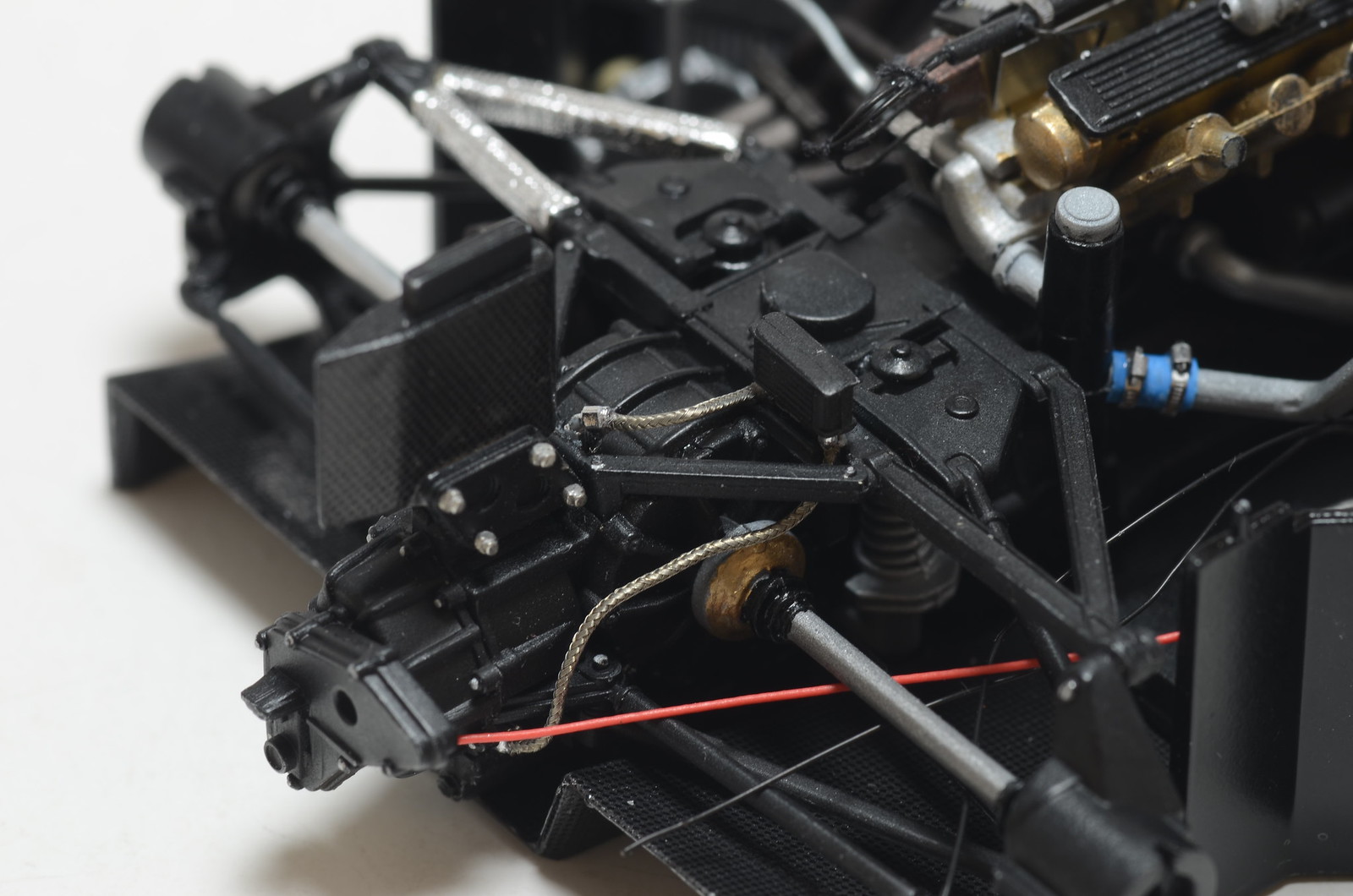

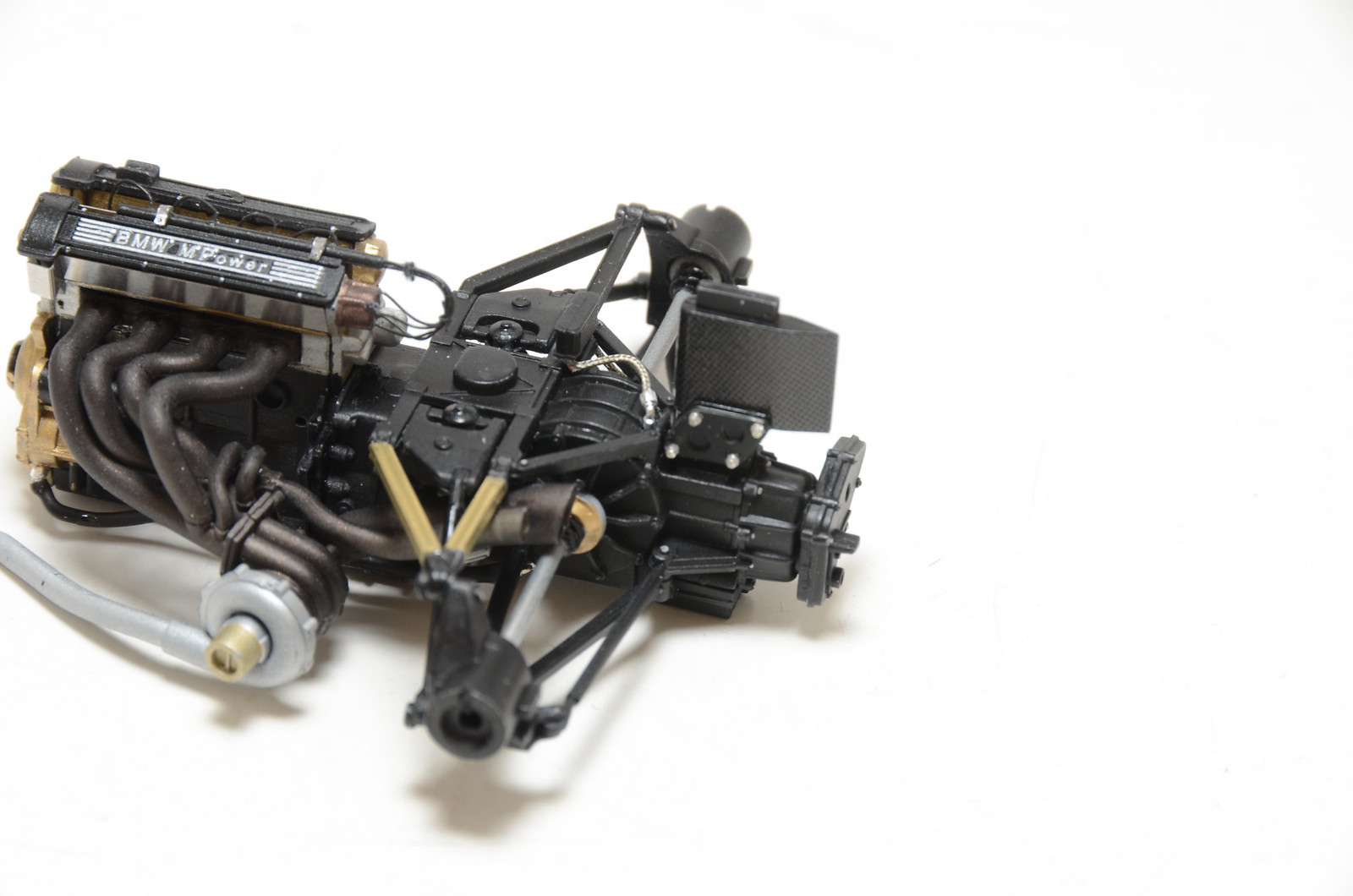

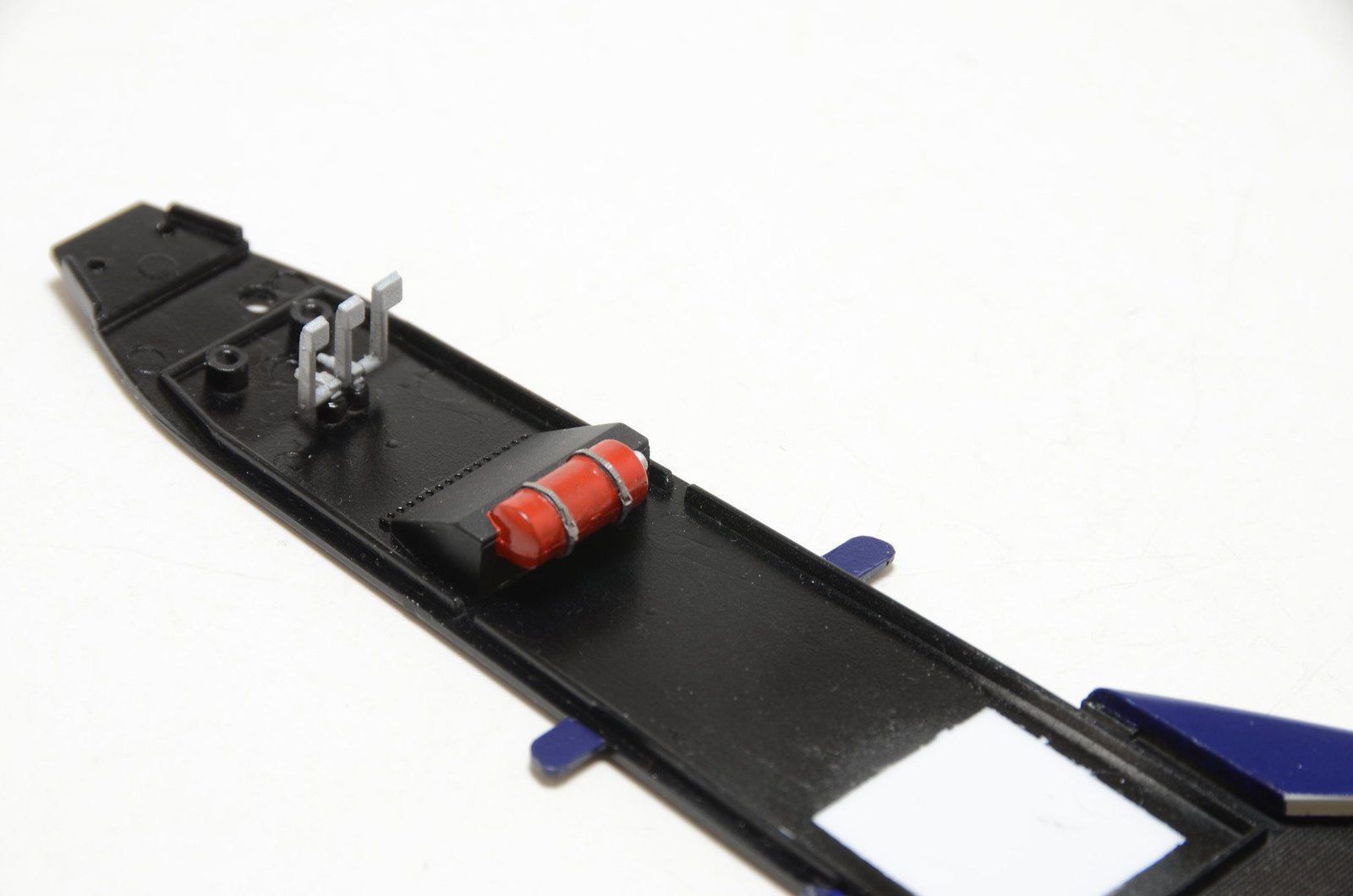

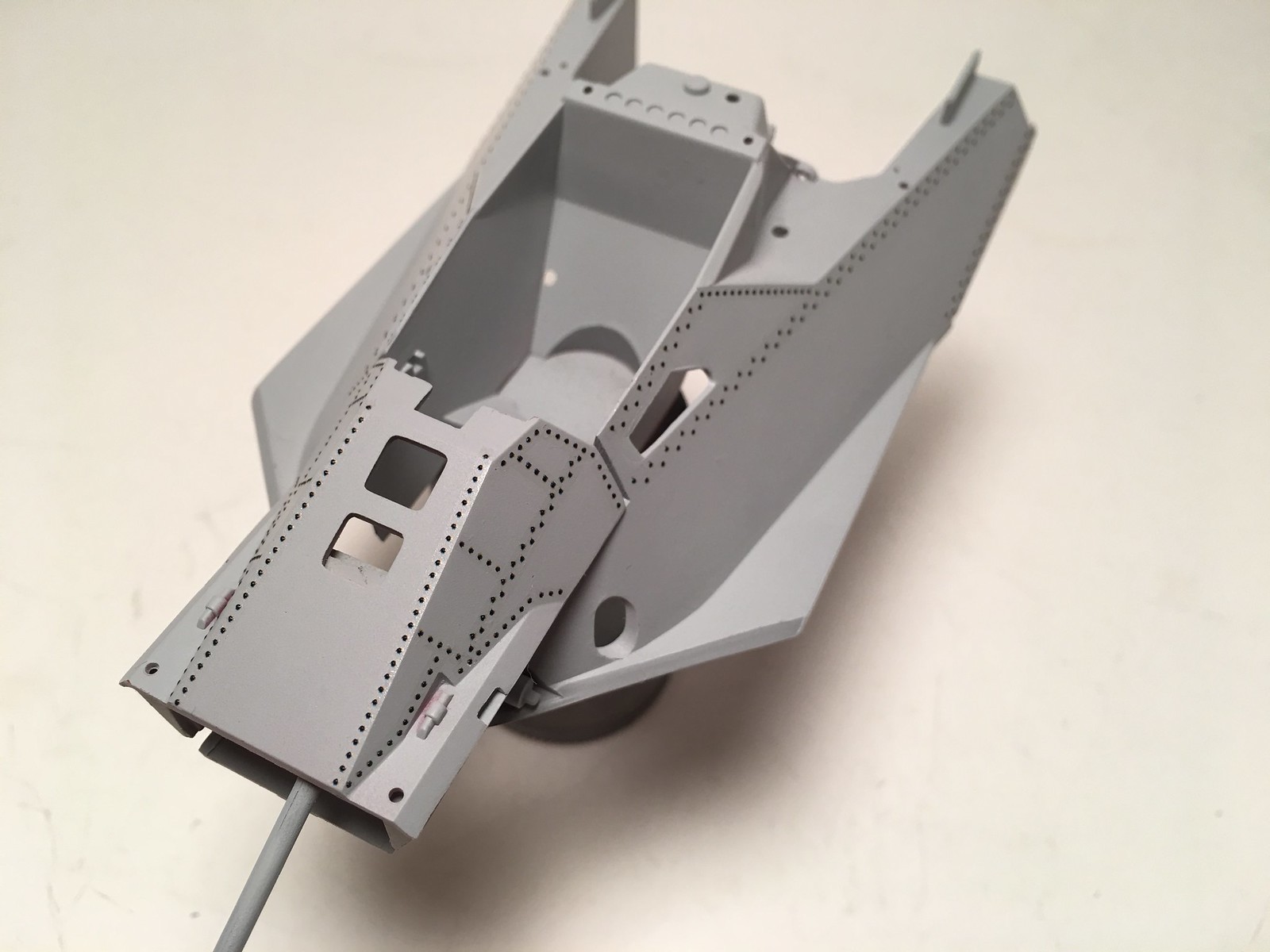

Few shots of current progress.